Deep-Processed Tea and the Role of Instant Tea

In the tea industry, “deep processing” refers to using fresh tea leaves, finished teas, by‑products, or tea residues as raw materials and, through appropriate physical, chemical, or biotechnological processes, turning them into new products that contain tea or tea-derived active components.

Against the backdrop of growing global tea production, instant tea powder manufacturing has become one of the most important directions in tea deep processing. It provides food and beverage manufacturers with a convenient, standardized form of tea that is easy to formulate and reproduce at scale.

What Is Instant Tea?

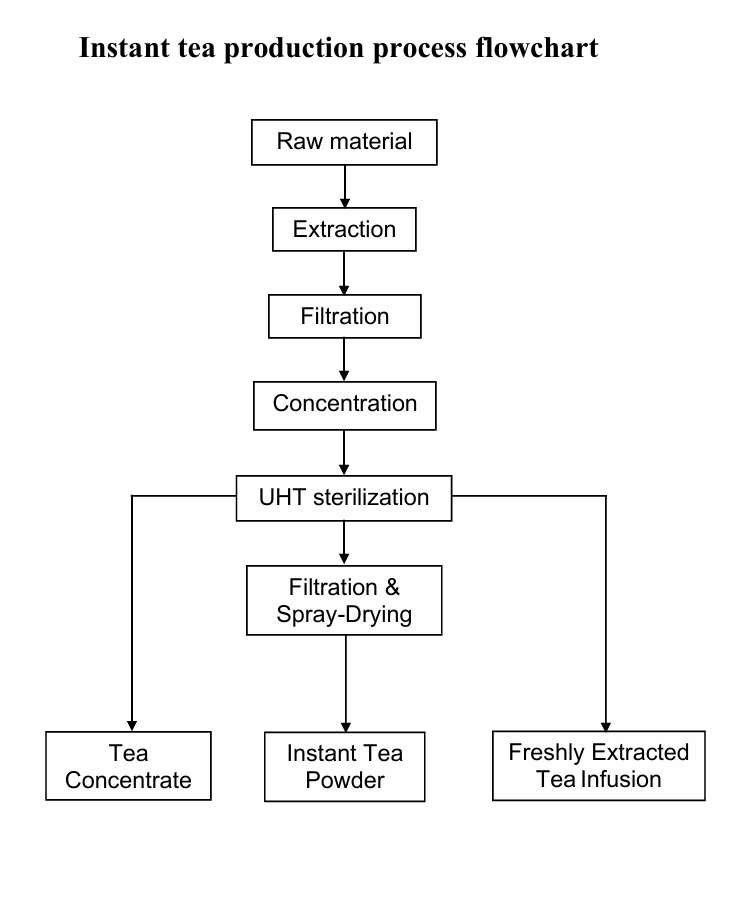

Instant tea, also referred to as extracted tea, is produced from finished tea. The tea is extracted with water, and the resulting tea liquor is then concentrated, sterilized, and dried to obtain a powder or granulated product that dissolves quickly in water.

For food and beverage manufacturers, instant tea powder serves both as a standardized tea base and as a formulation-friendly ingredient that delivers tea’s color, aroma, taste and part of its bioactive components.

As such, it has been widely adopted in tea beverages, blended drinks, bakery products, ice cream and frozen desserts, as well as various snack and seasoning applications.

How Is Instant Tea Powder Produced?

Raw Material Selection

Instant tea powder can be produced from finished teas. The diversity of tea raw materials gives instant tea products a wide range of flavor profiles and nutritional characteristics.

Depending on the starting tea, common product types include:

- Instant green tea,

- Instant black tea,

- Instant oolong tea,

- Instant dark tea (including Pu‑erh),

- Instant white tea,

- Instant yellow tea, and

- Instant jasmine tea and other scented teas.

Before entering the extraction stage, the tea typically undergoes basic pre‑treatment:

- Cleaning and grading – Removing foreign matter such as metal fragments, stones, and fibers by sieving, air separation, and magnetic separation;

- Cutting or coarse milling – Cutting or coarsely grinding the tea to an appropriate particle size. This improves mass transfer and the release of soluble components, but avoids making the powder too fine, which would increase the load on subsequent clarification and filtration.

The objective at this stage is to prepare a clean, uniform raw material that supports stable and reproducible extraction.

Extraction

Extraction is one of the core steps in instant tea production. It governs how tea polyphenols, caffeine, amino acids, and other soluble components are transferred from tea leaves into water, and in what proportions.

In industrial practice, water is usually the only extraction medium. Tea is soaked or extracted so that its soluble components dissolve into the water. Depending on product positioning and equipment conditions, several extraction approaches may be used, for example:

- Hot water infusion – Using hot water at controlled temperature and time to extract soluble solids;

- Ultrasonic-assisted extraction – Applying ultrasound to enhance mass transfer and shorten extraction time;

- Supercritical CO₂ extraction (combined processes) – In certain advanced processes, supercritical CO₂ can be used in combination with water extraction to selectively enrich or adjust aroma and specific components.

Clarification and Filtration

The crude tea liquor obtained after extraction contains fine tea particles, colloidal substances, and precursors of tea cream. If not properly treated, these components will negatively affect the solubility, clarity, and appearance stability of the final instant tea powder.

A typical clarification and filtration route may include:

- Removing coarse particles through sieves, filter cloths, or similar equipment;

- Using high‑speed centrifuges (such as disc or tubular centrifuges) to remove fine suspended solids and part of the colloidal fraction, thereby improving liquor clarity;

- For products that require high transparency and good cold‑water solubility, applying microfiltration or ultrafiltration to further remove fine particles and high‑molecular‑weight components.

For products where a certain “original tea” character is desired, producers will balance clarification level against mouthfeel, instead of pursuing maximum transparency.

The degree of clarification achieved in this stage directly affects the dissolution rate, clarity, and stability of the final product when reconstituted in cold or ambient water.

Concentration and Aroma Recovery

Tea Liquor Concentration

After extraction and clarification, the solids content of the tea liquor is relatively low. If it were dried directly, the energy consumption would be very high. Therefore, the liquor is first concentrated to an appropriate level.

Common concentration methods include:

- Vacuum evaporation – Under reduced pressure and lower boiling temperatures, water is evaporated and the tea liquor is concentrated to a target solids level (for example, around 20–40%). This helps reduce energy consumption while limiting thermal damage to sensitive components;

- Membrane concentration (reverse osmosis) – Using semi‑permeable membranes to separate water from soluble solids. This can be used on its own or in combination with vacuum evaporation to improve energy efficiency.

During production, online instruments are typically used to monitor concentration, ensuring that the tea concentrate entering the drying stage remains within the specified range for stable operation and product consistency.

Aroma Recovery and Re‑Addition (Optional)

During high‑temperature extraction and evaporation, part of the volatile aroma compounds naturally escape with the steam. To improve aroma retention in the final product, many high‑end processes include an aroma recovery and re‑addition step:

- Steam carrying tea aroma is condensed or absorbed in dedicated equipment to obtain an aroma condensate;

- Before spray drying, this recovered aroma is dosed back into the tea concentrate, or applied to the powder surface after drying.

In this way, the process can partially compensate for the impact of high‑temperature operations on tea aroma, and help the reconstituted beverage more closely resemble freshly brewed tea in its aromatic profile.

Drying: From Tea Concentrate to Instant Tea Powder

The concentrated tea extract is then dried. The goals of this step are to remove water from the concentrate, shape the particles, fix quality attributes, and obtain the finished instant tea powder. In most cases, the residual moisture content of instant tea powder is controlled below about 4%.

There are several drying methods available, such as spray drying and freeze drying. This article focuses on spray drying, which is the most common and mature method in instant tea production.

In spray drying, the tea concentrate is atomized into fine droplets and brought into contact with hot air. Water evaporates almost instantly, forming small, dry tea powder particles.

Key characteristics include:

- Very fast drying, enabling large‑scale, continuous production;

- Relatively favorable cost structure, making it suitable for industrial food and beverage formulations;

- By adjusting the inlet air temperature, outlet temperature, and feed rate, producers can balance drying efficiency with the retention of aroma and color;

- The finished product’s moisture content is maintained at a low level, which is beneficial for storage stability and transport.

What This Means for Food & Beverage Manufacturers?

In practice, the production of instant tea powder is fundamentally different from simply milling tea leaves into a ground tea powder such as matcha. It is a complete industrial process designed around standardizing tea flavor, ensuring consistent quality, and improve ease of use in downstream applications.

From raw material selection, extraction, clarification and concentration through to drying, powder handling and packaging, every step is designed to balance flavor, color, functional components and cost, while delivering a standardized and easy-to-use tea ingredient for industrial applications.

For food and beverage manufacturers, understanding the basic process logic behind instant tea powder can support more informed communication with suppliers, and enable more precise decisions in product development and ingredient selection.

If you are developing a new beverage, dessert or snack and need a reliable instant tea powder supplier, our R&D and sales teams can help you select the right tea type, solids level and processing parameters for your formulation. Feel free to contact us for sample requests or technical discussions.

For more information about our instant tea powder portfolio, see our Instant Tea Powder product range.

FAQ: Instant Tea Powder for F&B Manufacturers

Q1. In industrial production, what advantages does instant tea powder offer over loose tea leaves?

When manufacturers brew directly from loose tea leaves, the taste, color and strength of the infusion can vary from batch to batch because of differences in origin, season, grade and brewing conditions. Instant tea powder, by contrast, is produced under controlled extraction and concentration conditions so that the solids content, flavor profile and other physicochemical properties are standardized. Once reconstituted, it delivers a much more reproducible tea profile, which makes process control and product quality far easier to manage at scale.

Q2. How is instant tea powder different from matcha or other ground tea powders?

Matcha and similar products are produced by finely grinding whole tea leaves into a powder, so the entire leaf is consumed. Instant tea powder, by contrast, is produced through an extraction–concentration–drying process. Only the soluble components are retained, and insoluble leaf material is removed during clarification and filtration. This leads to different mouthfeel, clarity and application properties.

Q3. In which types of products can instant tea powder be used?

Instant tea powders are widely used in ready-to-drink teas, blended beverages (such as tea with fruit juice, dairy or plant protein), tea-flavored bakery and confectionery, ice cream and frozen desserts, snacks, seasonings and functional drinks. They provide tea flavor and color in a convenient, standardized format for manufacturing.